Das Nagar: In the sweltering heat of the foundry, the air thick with the scent of molten iron, workers toiled tirelessly amid roaring flames and searing temperatures, amid the rhythmic clangs and hisses of the casting process. Sweat trickled down their brows as they laboured over the moulds, pouring fiery liquid into intricate patterns. They were casting manhole covers that would soon grace the streets of countries like the USA and the UK, among others. For several decades now, manhole covers made at the foundries in Dasnagar, in West Bengal’s Howrah district, around 15 km from Kolkata, have found their way to foreign shores.

If you have been to New York, it is commonplace to find manhole covers with ‘Made in India’ embossed on them. The majority of them in New York City and thousands found across the United States are, in fact, manufactured 8,000 miles away in the quaint town of Dasnagar.

India is among the top three foundry producers in the world, and Bengal is the largest producer of ferrous and non-ferrous cast iron products in the country. Of the 300 foundries in Bengal, 95 percent of these units are concentrated in the district of Howrah. Some foundries date back to the 19th century.

Not only the US, foundries in Howrah export manhole covers also to European countries like the UK, Italy, Germany, Romania, Belgium, Portugal and even to the UAE. Additionally, sewer grates, water metres, and other castings are also supplied to US municipalities by India.

A visit to one such unit, Jagannath Iron Foundry, seemed like being transported to the 90s era. Inside, workers in vests and shorts, covered in coke dust and sweat, were casting moulds in sand while another batch hand-painted the finished plates as Kumar Sanu’s song “Deewana Dil Dhoonde Mashooq Ek Aisi” of the 1992 film Mashooq floated in the background amid clanging sounds.

A few women were also working inside, but most of the strenuous work was done by the men. The temperature outside the factory touched 40 degrees Celsius. Inside, the area felt like an oven and seemed to be five degrees hotter.

Why Developed Nations Like US And UK Buy Manhole Covers From Dasnagar

Howrah Foundry Association general secretary Satyajit Kundu said labour who specialise in moulding skills was readily available in Bengal.

“The casting process we follow is found mainly in India and China and our products are cheaper than other countries. However, anti-dumping duties by the US have rendered China uncompetitive and thus, India has become the main supplier,” Kundu said.

Apart from specialised labour, cost arbitrage was a major factor why foreign nations prefer to import manhole covers from India. “The cost of making these covers, say in America, is much more than making it here in India. We are still following old molding technologies and workers rely mainly on strength and bare hands rather than machinery. So, the cost works out cheaper,” said Aayush Madhogaria of Jagannath Iron Foundry.

Manhole covers are made out of cast iron. Cast iron means that the iron is melted and then poured, or cast, into a mold. Special manhole covers, like those found in airports, are made of ductile cast iron, because of its greater strength.

The Madhogarias have been running Jagannath Iron Foundry in Howrah for nearly five decades. The foundry was started by Aayush’s grandfather Basant Lal Madhogaria, an iron and steel trader, in 1972.

The foundry exports manhole covers to around 25 nations and a bulk of their products are bought by Arab nations. Around 10,000-15,000 tonnes of manhole covers and other castings (municipal and sanitary castings) are exported per month from the eastern belt, Aayush said.

Cheap Labour, Easy Availability Of Raw Materials

BD Agarwal, managing director of Howrah Ferrous Limited, said making manhole covers was a labour-intensive job and labour cost was much higher in other countries. “Countries like the US don’t have labour intensive industries, they have modern foundries. Bengal has an abundance of labour-intensive industries. So it is much cheaper,” Agarwal said.

He said traders and agents of specific countries purchase the materials from them and then they sell them to the concerned government departments. “Even after adding freight cost and duties, the manhole covers work out to be 30 per cent cheaper for the countries,” he said.

A tonne of manhole covers can cost anywhere between Rs 90,000 and Rs 1 lakh, and it depends on the size, weight and drillings.

“In the US, every city has its own markings and sizes. For example, the manhole cover taken by New York City won’t be taken by Houston or Oklahoma. Each municipality has their own specifications, drawings, markings,” Agarwal said.

Another factor that comes as a boon for the Howrah foundries is the easy availability of raw materials. “Raw materials like pig iron are easily available from Jamshedpur and Odisha. US and UK foundries are shutting down due to pollution concerns. This advantage is being taken by India,” said Shayak Das, co-ordinator of MS Nandy Iron Foundry.

Shortage Of Skilled Labour Plaguing Industry

However, the very factor that led to mushrooming of the industry in Howrah is turning out to be a major reason for its decline — skilled labour. Most of the foundries in Howrah are MSMEs and they haven’t invested in modernisation of technology.

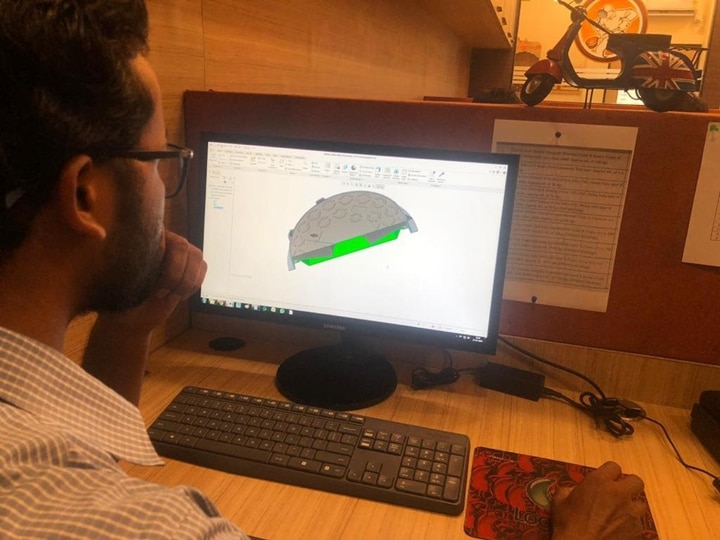

Acknowledging that finding labour was a major issue for the industry, Aayush Madhogaria said: “We are not getting the specialised labour like that of old. Thus, we are trying to modernise and mechanise the industry so that we can reduce labour dependence. Many of them are now going outside Bengal.”

Agarwal of Howrah Ferrous Ltd concurred: “Nowadays, no person wants his son to come into this job. They want their sons to be educated and pursue IT, CA. So, we are getting shortage of hands gradually.”

While the golden days of Howrah’s foundry industry may be over, its products are still in demand globally as was shown in the 2014 documentary ‘Cast in India’, which brought renewed spotlight on India made manhole covers across the US.

IN PICS | Tracing The Journey Of Manhole Covers Made In Kolkata’s Dasnagar To US, UK, UAE